Cloud-based simulation of high-temperature concentric chimneys

May 5, 2021 2021-05-20 22:43Cloud-based simulation of high-temperature concentric chimneys

Cloud-based simulation of high-temperature concentric chimneys (fortissimo-project.eu)

DINAK is a Spanish SME expert in designing, manufacturing and installing domestic and industrial chimneys and ventilation systems. DINAK needs to improve its capabilities to be competitive in a global market. The reduction of CO2 emissions and the more efficient use of energy require the design of optimised chimneys. The optimisation of chimneys involves many variables and physical testing is not feasible on the grounds of cost and time. DINAK needs a simple and powerful tool to analyse and test the design of exhaust chimneys. This tool should help them to improve the design of concentric chimneys and gain understanding of the physical phenomena involved in exhaust processes. To reduce design times to reasonable levels, High Performance Computing (HPC) has become an essential component in the development of such a design tool.

Fortissimo_SuccessStory_505_DINAK.pdf

The Challenge

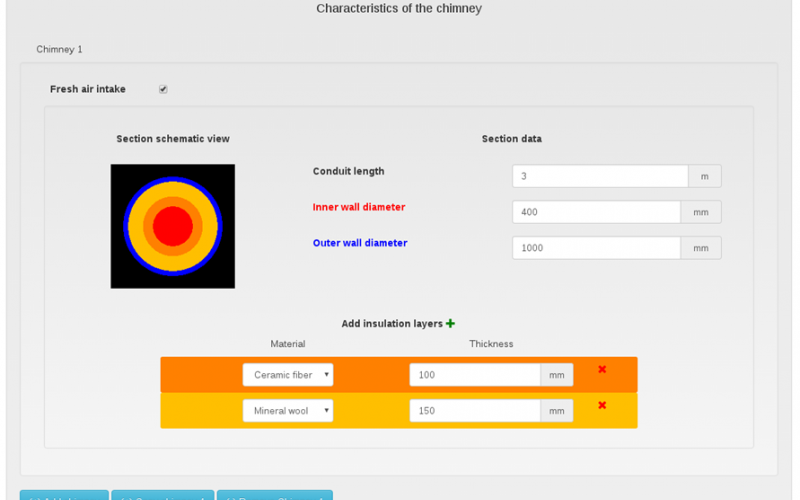

The reduction of emissions requires the design of optimised chimneys. Simulation plays an important role in the design of new chimneys. In a building with stoves it is necessary to install a ventilation system to assure an effective and regulation-compliant exhaust system and a proper air renovation ratio. The concentric chimney designed in this experiment is a countercurrent design, where flows have different directions: The inner tube leads hot combustion gases to the exterior and the external cylinder directs fresh air from the exterior providing oxygen to the stove. If the chimney is not properly designed, not enough oxygen will reach the stove and combustion will be inefficient. There are many variables involved in the optimization of the design of a chimney and physical testing is not feasible on the grounds of cost and time. Consequently, it is necessary to use advanced numerical tools. The problem is complex because there are many variables and the simulation must be sufficiently accurate and detailed. High performance computing (HPC) is needed for a fast time-to-solution, supported by a user-friendly interface to make the simulations easily accessible. The implementation of such a solution is the task of this experiment.

The Solution

Before this experiment DINAK did not have access to HPC-based simulation and had no experience in its use. It needed approximately a month of work for the design and testing of a new chimney. Every new product required the work of 3 specialised engineers and 2 craftsmen to assess the different options, to design prototypes and manufacture them and to test complete chimneys to verify the initial design concept. Now it has a reliable HPC-based simulation, based around the open-source Open Foam package, DINAK can shorten the whole design process down to one week. Moreover, the user-interface provides the ability to explore the design space in a systematic way which can improve the quality of the resulting designs. This experiment has demonstrated that the design of concentric chimneys using HPC-based simulation resources is feasible and accurate. The results from this solution have been successfully validated against commercial software and experimental data.

The Benefits

HPC simulation enables DINAK to accelerate and optimise the design of concentric chimneys. Faster design will allow DINAK to enter new markets and to increase its competitiveness. Experience shows that the first company with a new design of chimney increases its market by 5% to 10%. Currently, DINAK develops around 3 to 4 new products per year and this advantage would increase its turnover by approximately €100K. Before this experiment, DINAK required approximately a month for the design and testing of a new chimney. The costs comprised 3 specialist engineers for 1 month (€9,300), 1 craftsman for 1 month (€2,100) and prototype costs of €2,000, totalling €13,400. Using HPC simulation taking 1 week, these costs reduce to 1 week of an engineer’s time (€900) and computing costs of €240 totalling €1,140. This gives DINAK a saving of over €12,250 per design which is €49,000 per year. The optimised design through the use of HPC, enables DINAK products to pass CE Mark tests with a zero failure rate with a consequent cost reduction. Previously there were 1 to 2 failures per year resulting in additional operating costs of around €6,000.

Based on experience gained in this experiment, UDC is planning to offer, via the Fortissimo marketplace, a consultancy service to develop web interfaces for cloud-based applications. AIMEN will be able to offer consultancy services in the Marketplace based on OpenSource modelling. CESGA will increase its sales of computer cycles by around 10,000 CPU hours per year. It will also improve its visualisation services and be able to use the outcome of this experiment as a reference to promote its services.

Companies Involved

End-user: DINAK

HPC Expert: UDC

Application Expert: AIMEN

HPC: Provider: CESGA